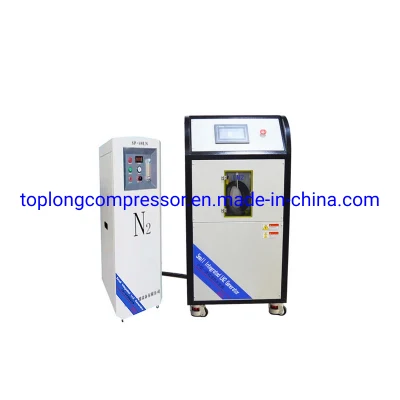

Equipo de generación de gas médico Generador de oxígeno médico Psa para planta de oxígeno hospitalario

Equipo de generación de gas médico Generador de oxígeno médico PSA para planta de oxígeno hospitalario Equipo de generac

Envíe su consultaDESCRIPCIÓN

Información básica

| N º de Modelo. | KSO-40 |

| Uso | Oxígeno |

| Objetivo | Fabricación de gases |

| Partes | Tanque de gas |

| Campos de aplicación | Químico |

| Nivel de ruido | Bajo |

| Tamaño de la máquina | Medio |

| Condición | Nuevo |

| Certificación | ISO, CE |

| Modelo | Kso-40 |

| Producción | 40 Nm3/H |

| Consumo efectivo de gas | 7 Nm3/min |

| Calibre de importación y exportación | Dn50 |

| Pureza | 94% |

| Paquete de transporte | Paquete de exportación estándar |

| Especificación | ISO, CE |

| Marca comercial | adekom |

| Origen | dong guan |

| Código hs | 8419609090 |

| Capacidad de producción | 50 por mes |

Descripción del Producto

Equipo de generación de gas médico Generador de oxígeno médico PSA para la planta de oxígeno del hospital Gerador médico do oxigênio PSA do equipamento médico da geração de gás para a planta de oxigênio do hospitalGenerador de O2 'Adekom' en constante mejora con un diseño de producto especial, flujo de proceso simplificado, que le ofrece nuevos concepto de generación de O2. KSO: el equipo generador de oxígeno PSA utiliza el tamiz molecular de carbono de alta calidad como adsorbente y utiliza el principio PSA, adquiriendo gas oxígeno directamente del aire comprimido.1.Under the pressure of certain because of kinetic effect, the spread rate of oxygen and nitrogen on carbon molecular sieve has big differences. As a great deal of oxygen molecules is adsorbed by carbon molecular sieve, nitrogen molecules enrich at gaseous phase, so nitrogen and oxygen get separated.2.As the adsorption capacity of carbon molecular sieve on oxygen changed with the pressure, different pressures have obvious difference, when reduce pressure,it can desorb the oxygen molecule adsorption on carbon molecular sieve, making carbon molecular sieve regeneration, like this make it recycling use.3.Choose two adsorption tower processes, one tower adsorption then produce oxygen, the other desorption regeneration, the two-circulation alternate, continuously output high quality of oxygen.Technical characteristics1. Unique molecular sieve protective measures so as to lengthen the service life of carbon molecular sieve.2. Self-reliance type cylinder pressure device can avoid high-speed airflow rushed out, it cannot cause of molecular sieve pulverization phenomenon, equipped with the limit settlement alarm system, when it reaches the floor level of journey, the equipment will sound and light alarm by itself.3. Configured DCS remote control system interface, it can monitor the system operate condition through the computer.4. Intelligent interlocking nitrogen vent device can guarantee the quality of nitrogen.5. Perfect process design and excellent energy conservation characteristics reduce the cost of gas.6. Reasonable structure design makes the transportation, sling and installation very convenient.7. Selecting the safe and reliable control components, so the equipment can run stable and reliable,it also has various fault alarm.8. It operates easily, runs stably, and has a high degree of automation, can realize no one operates.System Flow Diagram of O2 Generator:It is important to make sure that the compressed air entering the O2 generator has already been dried and purified with adequate air treatment system equipment like air receiver, Refrigerated Air dryer, inline air filters to ensure air dew point temperature, particle size of less than 0.01 micron in order not to contaminate the absorbent inside the O2 generator.ADEKOM (ASIA PACIFIC) LIMITED founded in the late 90's is a specialized air/gas compressors and treatment system manufacturer with headquarter in Hong Kong. Its partners located in Vicenza, Italy and Germering, Germany are the world's leading manufacturers with global recognition and experience in designing, manufacturing and marketing of rotary screw air/gas compressors for decades. QUALITY, RELIABILITY and ENERGY EFFICIENCY have been the main objectives of serving customers all over the world. ADEKOM follows the company core of its European partners, is committed to the research & development, quality assurance and satisfaction of customers' needs. Today, what ADEKOM can do is not just to supply the best products to the market, but to provide THE TOTAL SOLUTION TO YOUR NEEDS!CONTACT USAsia Pacific Market : Spencer Lau (Ms.) European/ Middle Eastern/ African Market: Echo Lok (Ms.) American Market: Alice Kwok (Ms.)

Productos relacionados

-

![Equipo de generación de gas médico Generador de oxígeno médico Psa para planta de oxígeno hospitalario]()

Equipo de generación de gas médico Generador de oxígeno médico Psa para planta de oxígeno hospitalario

-

![Generador de oxígeno de inicio de un botón para uso médico, acuicultura, soldadura y minerales]()

Generador de oxígeno de inicio de un botón para uso médico, acuicultura, soldadura y minerales

-

![Concentrador de oxígeno de viaje ligero Concentrador de oxígeno de coche al aire libre con batería Mini portátil 1L 3L 10L Generador Precio Pulso Concentrador de oxígeno portátil]()

Concentrador de oxígeno de viaje ligero Concentrador de oxígeno de coche al aire libre con batería Mini portátil 1L 3L 10L Generador Precio Pulso Concentrador de oxígeno portátil

-

![Concentrador de oxígeno de perfil de extrusión de aluminio para uso doméstico Oxygenerator/Torre de absorción de oxígeno]()

Concentrador de oxígeno de perfil de extrusión de aluminio para uso doméstico Oxygenerator/Torre de absorción de oxígeno